1 Batching

Use a mixer to mix the following materials evenly: 12% dolomite, 1% other, 49% quartz sand, 16% soda ash, 18% cullet, 4% limestone

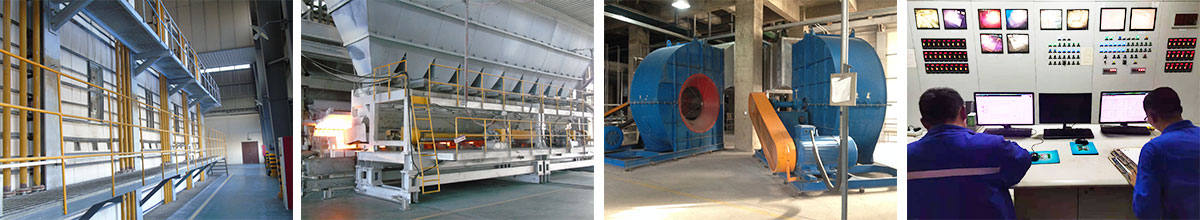

2 Melting

Glass melting furnace is a thermal equipment that melts batch materials into glass. The batch materials of glass undergo a series of physical and physicochemical reactions in the melting furnace to form a glass liquid, and then undergo refining and homogenization. Homogenizie, cooling.

3 Rolling process

Rolling process is one of the forming methods of flat glass. The molten glass drawn from the furnace is pressed with a pair of water-cooled rolling rolls to form glass with a specific pattern and thickness.

4 Cutting

Cutting equipment (cross-cutting machine + slitting machine) cuts the entire plate of glass into the specifications and dimensions required by the customer's order.

Original film manual inspection + automatic defect detection equipment = 100% full inspection

5 Packing

Glass sheet collection equipment: Fully automatic manipulator equipment is adopted, which greatly saves stacking and loading and unloading time, and greatly reduces work hazards

Qualified product packaging: Finally, the original sheets that have passed the inspection are cut according to the customer's requirements, and the products are packaged and stored.

Product display

Focus on the production of solar ultra white photovoltaic original glass, coated tempered glass products manufacturingTypes and specifications of original glass

2021-05-15Types and specifications of original glassThe simple classification of glass is mainly divided into flat glass and deep-p…The main process of glass coating processing

2021-05-15Glass coating is a kind of chemical polymer material. Because of its high-density chemical properties, it is used in the …The purpose and correct operation of the glass edging machine

2021-05-15Precautions for the correct operation of the glass edging machine1. For the newly purchased edging machine, be sure to re…The benefits of using ultra-white glass for photovoltaic glass

2021-05-15The advantages of using ultra-white glass for photovoltaic glass:1. Low self-defense rate of glassIt can protect cultural…

Products

Contacts

Landline

Collectionand supply:+86-83837701Mailbox

Collectionand supply:caigoubu@syxdxcl.comFax

Fax:+86-0527-87872016

Online Message